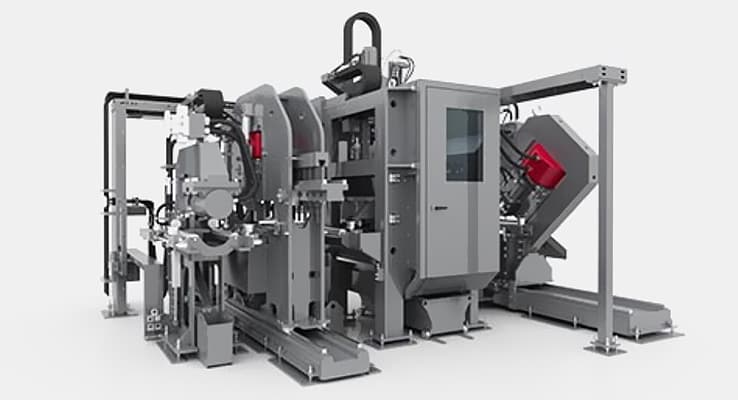

Structural Fabrication Machinery Birmingham Al

Gulf States Saw & Machine Company was established in Tampa, FL in 1984. Its mission is to help clients get the best products in the metal cutting sector. CMT's operations expanded to serve the whole south, with additional showrooms opening in Atlanta, GA and Dallas TX. Capital's presence can now be felt in 12 states, including Florida, South Carolina. Virginia, Mississippi. Tennessee. Texas. Georgia. North Carolina. Alabama. Louisiana. Oklahoma.